Conventional and most common type of water level monitoring equipment used on any package boilers are the Bronze Glass tube type water level gauge. Effective to give accurate water level reading on the boiler the glass tube is protected by a toughened glass protector for an all angle viewing. This model is suitable for most water tube boilers, which run on High Pressure and Temperature applications.

Product Description

This protector eliminates any harm or injury which can be caused in case of glass tube breakage. Most Gauge Cocks for this version on water level gauge comes equipped with a safety ball to prevent loss of water from the boiler when a glass tube breaks. Suitable for most low pressure and temperature package boilers.

Having the glass tube breaking all the time effects production and creates loss time for the any production unit. Thus, most boiler manufacturers opt to use a Gauge glass instead of a glass tube for most boiler water level monitoring system. Like the glass tube, this version also gives accurate and clear indication of the water level in any boiler. Gauge glasses in two versions. Reflex and transparent for high pressure application. Most gauge glasses are used with specially designed compound gaskets to protect the glass for prolonged usage. Transparent gauge glasses are also used with Mica Shields to protect during high-pressure usage. Most gaskets are asbestos based and now gaskets made of non-asbestos and pure graphite are also available. This version also has very minimal glass breakage, as the gauge glass is design to be shock resistant.

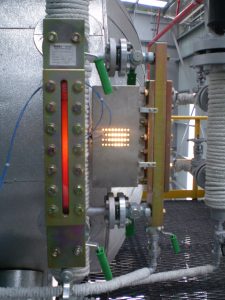

Most commonly used for easy viewing with light assistance as most big capacity water tube boilers are quite big and high therefore making it difficult to view on normal situations. Illuminators are fitted with colour screens to give accurate indications of boiler water levels, which is an important element to monitor at all times.